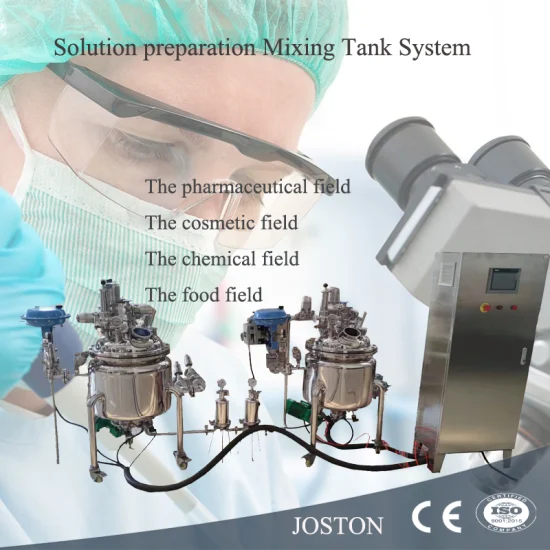

Joston Eye Drop Liquid Solution Glue Western Medicine Preparation Mixing Tank System

solution preparation system can be used for the different fields ,like the pharmaceutical field which can be used in the

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | JPG |

| Customized | Customized |

| Condition | New |

| Warranty | 1 Year |

| After-sales Service | Online Support/Visit Client′s Plant Site |

| Heating Method | Steam /Electrical /Hot Water /Thermal Oil |

| Tank Layer | Single Layer/Jacket Type /Double Jacket |

| Bottom Mounted Agitator | Magnetic /High Shear Emulsifying Type |

| Top Mounted Agitator | Propeller /Anchor/Scraper /Emulsifying Type |

| Cooling Method | Chiller/Cooling Water /Liquid Nitrogen |

| Function | Mix One or Several Materials Together |

| Output | Liquid Solution/Suspension/Cream |

| Feeding | Liquid/Power+ Water (Solvent) Liquid |

| Pharmcautical Product | Eyedrop ,IV Solution ,Ampoule,Syrup,Vaccine |

| Food Product | Juice ,Milk ,Honey,Chocolate ,Cream ,Ketup,Yogurt |

| Transport Package | Wooden Case Packaging/According to Customer |

| Specification | 20L-50000L |

| Trademark | JOSTON |

| Origin | Wenzhou, China |

| HS Code | 8479820090 |

| Production Capacity | 30 Sets/Month |

Product Description

solution preparation system can be used for the different fields ,like the pharmaceutical field which can be used in the low viscosity solution like infusion solution ,injection solution ,eye drop solution ,syrup solution ,oral liquid,vaccine,lotion etc ,in the cosmetic field ,it can be used for the cream ,ointment ,hand sterilizer etc ,for the food field ,it can be used for the juice process machine ,milk cooling tank ,beverage preparation etc .also can be used for the chemical field ,like the solvent blend -ethanol ,methanol ,acetone etc .In the pharmaceutical field ,the solution preparation system is used to WFI water with Pharmaceutical API together according to the technological proportions. Which can be used in the infusion water ,injection solution etc ,the tank is designed company with CIP/SIP system ,can be PLC automatic control the whole production process .solution preparation system can be standardized and humanized according to the requirements of production process. In the mixing process, it can realize the feed control, discharge control, mixing control and other manual and automatic control.solution preparation system is composed of mixing tank body, upper and lower heads, agitator, support, transmission device, shaft seal device, etc. heating device or cooling device or metering device can also be configured according to process requirements.solution preparation system Nozzle configuration:The process nozzles mainly include manholes, inlets, outlets, sight glass, sight lights, vent filter, CIP (equipped with sanitary universal cleaning balls), SIP ports, sterile sampling ports, thermometers, temperature sensors, jacket inlets and outlets.(Nozzle size and opening position shall be provided according to process requirements.)

Components Item | Function and usage |

CIP spray ball | Wash &clean tank inside surface and devices automatic ,which should connect to the CIP machine station |

Vent filter | Filter air to prevent the bacteria into the tank ,also can release the tank inside pressure. |

Temperature sensor (gauge) | Indicate inside tank temperature and PID temperature control with the necessary valve and fittings |

Pressure sensor (gauge) | Indicate the inside tank pressure |

PH sensor | Indicate the product PH data |

conductivity meter | Indicate the product conductivity data |

Level sensor (gauge) | Indicate the inside tank product level height ,there are have different models :(static) pressure type ,ultrasonic type ,radartype ,glass tube type ,plate sight glass type . |

Load cell | Indicate the product weight |

VFD ( inverter ) | Control and adjust agitator speed |

Safety valve | Release inside tank pressure to protect the tank safety |

Flow meter | Indicate the solution inlet and outlet volume |

Sight light | Indicate inside tank bright for watching easily |

Manhole (handhole ) | Charge solid product into tank ,also can be used for maintenance inside tank components. |

Sampling valve | Take inside tank products sample for offline checking |

ModelItem | JPG-100 | JPG-500 | JPG-1000 | JPG-3000 | JPG-6000 |

Tank work volume:L | 100 | 500 | 1000 | 3000 | 6000 |

Motor power high shear emulsifying:Kw | 1.1 | 1.2 | 4.0 | 7.5 | 22 |

Agitator speed for high shear emulsifying :RPM | 0-1440 or 0-2900 | ||||

Motor power propeller type agitator g:Kw | 0.37 | 1.5 | 2.2 | 4.0 | 7.5 |

Agitator speed for propeller type agitator :RPM | 0-150 | ||||

Inside shell pressure MPa | -0.1/0.3 (can be done as client's URS) | ||||

Jacket pressure MPa | 0.3 (can be done as client's URS) | ||||

Jacket heating medium | Steam /hot water/electrical heating | ||||

Cooling medium | Chiller /cooling water /tap water | ||||

SERVICE

We have established some overseas agent office to make the after-sales serivce already ,so it can will be service client in fast response .also in our headquarter service team ,there is a expert team which can support client in 7*24 hours .1. Customer inquiry and consultation (URS documents)2. Confirmation of treatment plan (DQ documents &PID Drawing)3.Quotation offer with the technolgy document (Quotation PI )4.Engineering and Manufacturing (Prodcution &Quality inspection )5. Product inspection (FAT documents)6. Delivery arrangement and loading work (full set Shipment documents)7. After-sales service (OQ,PQ ,SAT documents)

FAQ

1.What about your factory?Our factory is located in Wenzhou city ,Zhejiang Province and have more than 15 years experience on machinery making.2.How will your company control the equipment quality ?We have a qualified expert team ,we will inspect every production proceed .also Machines will be tested in our plant before shipment .3.How long the warranty will be?We provide 1 years warranty for the machine running ,but we will afford whole -life service for the machine .4.Which kind payment do your company do now ?We accept Western Union, T/T ,D/P,D/C and irrevocable L/C payable etc.5.Can we become your distributor in our country?Yes, we very welcome you! More details will be discussed if you are interested in being our agent.6.Why we choose "JOSTON "?1. We enhance the reliability of product's quality and working life . 2. We decrease the consumption cost of the product in the ruuning. 3. We improve research personnel's ability to deliver a creative design; 4. We use leading technologies in our product development and innovation, and thereby increase the competitive advantage of products.7.Do you supply installation equipment in oversea?Yes, if need, we can send our engineer to your plant to help you do installation and commission.8.How can we know the order production status ?We will arrange the person to take photo or video during manufacturing in every week to make you to know the production status.When goods are finished,we will take detailed photos or video for your checking ,after approve ,then we will arrange shipment .also you can arrange FAT in our plant when the goods is ready here9.what is kind service do you offer before making order ?1.according to your company URS ,we will make the design drawing accoridingly.2.after your company approved drawing ,we will make quotation.3. final we make agreement on payment terms ,delivery time ,package ,shipment etc.10.how about your company after-sale serivce ?1. We provide long-term after-sale service. 2. we can do installation and commission for the equipment in your plant if necessary .3. Meanwhile, you can call or e-mail us to consult on any relevant question since we have a special line for after-sale service. Alternatively, you can communicate on-line with us to solve any problem.

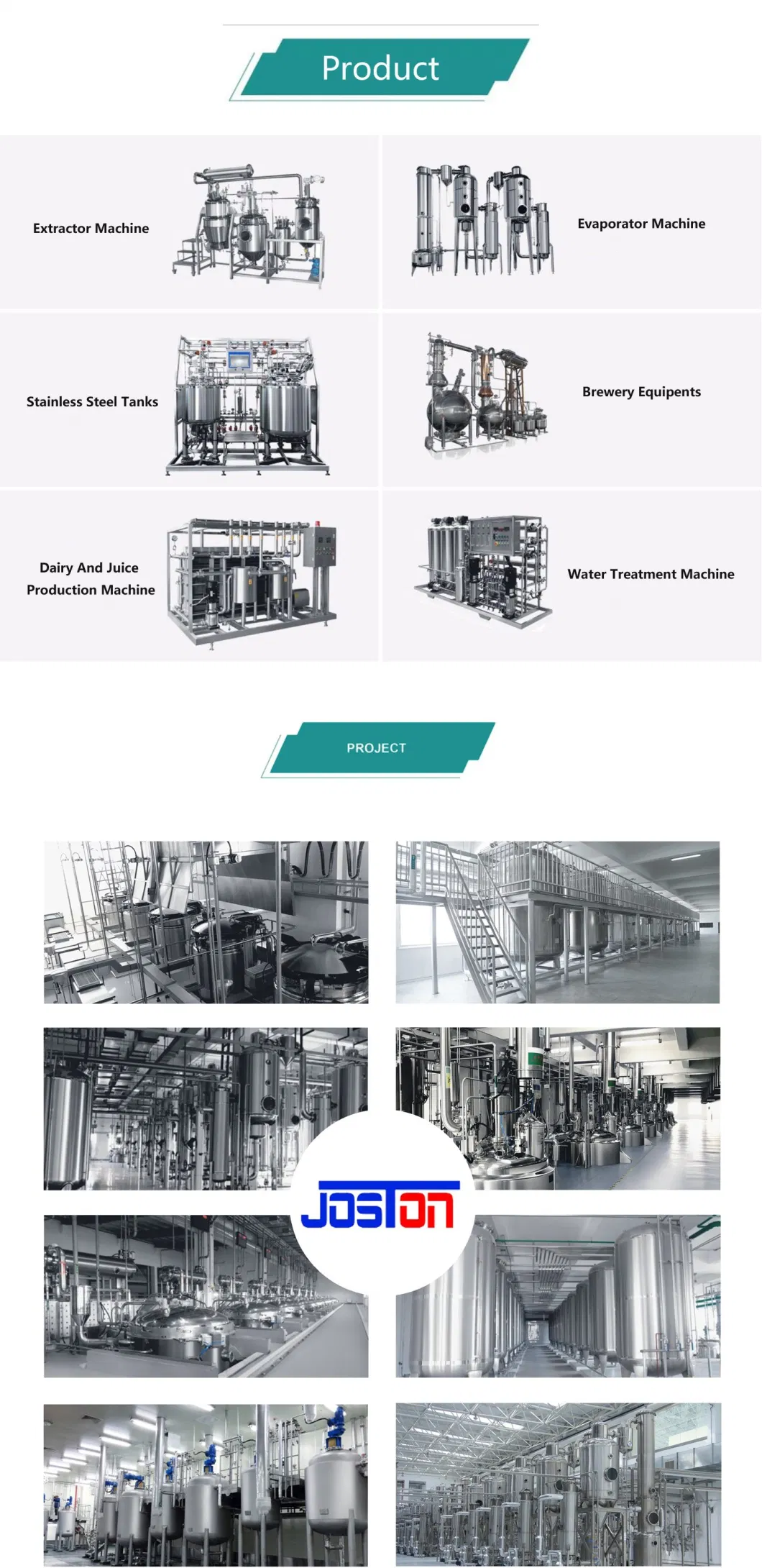

Related Products

-

![High Quality Recirculating Batch Bin Dryer Grain Bin Drying Systems]()

High Quality Recirculating Batch Bin Dryer Grain Bin Drying Systems

-

![Little 0.5t Fuel Oil Steam Boiler System for Wood Drying Machine]()

Little 0.5t Fuel Oil Steam Boiler System for Wood Drying Machine

-

![Risense drive through conveyor belt car wash tunnel system full automatic with air dryer and drying brushes]()

Risense drive through conveyor belt car wash tunnel system full automatic with air dryer and drying brushes

-

![Pharmaceutical Gelatin Capsule Softgel Encapsulation Paintball Maker Highly Efficient Soft Gel Gelatin Capsule Making Filling Machine]()

Pharmaceutical Gelatin Capsule Softgel Encapsulation Paintball Maker Highly Efficient Soft Gel Gelatin Capsule Making Filling Machine